| Model | 3000HP FRAC FLEET | 2500HP FRAC FLEET |

|---|---|---|

| Engine Rating | 3000 HP | 2500 HP |

| Max. Displacement | 1020 gpm (3860 L/min) | 673 gpm (2547 L/min) |

| Max. Working Pressure | 20,000 psi (140 MPa) | 15,000 psi (105 MPa) |

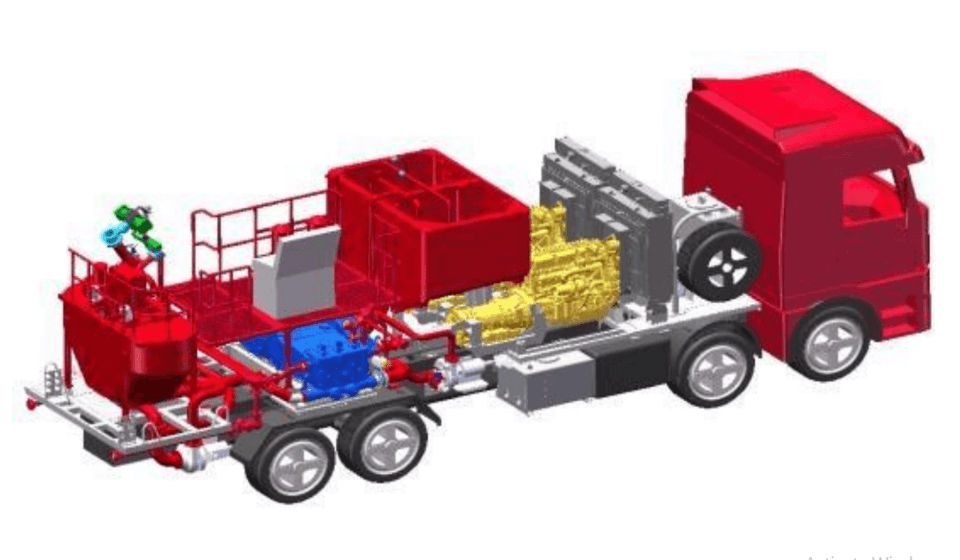

| Chassis | MAN BENZ | MAN BENZ or upon request |

| Frac Pump | 5-cylinder or 3-cylinder | 5-cylinder or 3-cylinder |

| Model | 130 BBL Blender | 100 BBL Blender |

|---|---|---|

| Max. Water Discharge Rate | 130 (20) | 100(16) |

| Max. Delivery Pressure | 100 (0.7) | 100 (0.7) |

| Max. Proppant input Capacity | 28570 (12960) | 23148 (10500) |

| Chassis | MAN BENZ or upon request | MAN BENZ or upon request |

| Model | 140MPa Manifold Truck | 105MPa Manifold Truck |

|---|---|---|

| High Pressure Manifold Rating Pressure | 20,000 psi (140 MPa) | 15,000 psi (105 MPa) |

| High Pressure Manifold Connections | 8 | 8 |

| High Pressure Connection Size | 3" FIG2002 | 3" FIG2002 / 4" FIG1502 |

| Chassis | MAN, BENZ or upon request | MAN, BENZ or upon request |

| Model | LSPE 32 Data Van |

|---|---|

| Max. Number of Fracturing Unit Controls | 32 |

| Max. Number of Blender Controls | 2 |

| Industrial Computers | 3 |

| Chassis | MAN, BENZ or upon request |

| Model | GJC100-30 |

|---|---|

| Max. Pressure | 14500 psi (100 MPa) |

| Max. Displacement | 793 gpm (3 m3/min) |

| Max. Mixing Capacity | 608 gpm (2.3 m3/min) |

| Cement Slurry Density | 1 to 2.6 g/cu.cm |

| Volume of Mixing Tank | 10 bbl |

| Model | Contimuous Mixing Skid |

|---|---|

| Max. fresh water flow of suction pump | 10 m3/min |

| Max. fresh water flow of discharge pump | 10 m3/min |

| Fluid feed pump displacement range | Gear pump : 50–400 Plunger pump : 20-100 |

| Mixing tank volume | 13 m3 |

| Powder tank volume | 5 m3 |

| Max. displacement of screw conveyor | 100 L/miN |

| Max. speed of agitator | 200 rpm |

| Concentration accuracy of solution | 2% |